Manufacture & Production

Whether considering the manufacture of a new, high volume product or that of a one-off, high technology machine, finding the optimum manufacturing route and best manufacturing partners is a key aspect of successful product and machine development. This enables clients to progress their new products to market quickly and reliably, thus maximising their return on investment.

Whether considering the manufacture of a new, high volume product or that of a one-off, high technology machine, finding the optimum manufacturing route and best manufacturing partners is a key aspect of successful product and machine development. This enables clients to progress their new products to market quickly and reliably, thus maximising their return on investment.

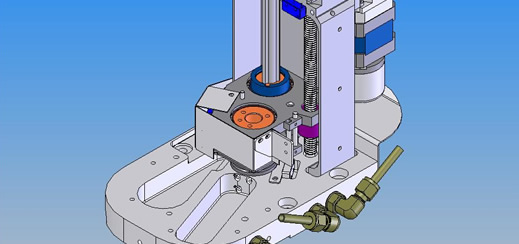

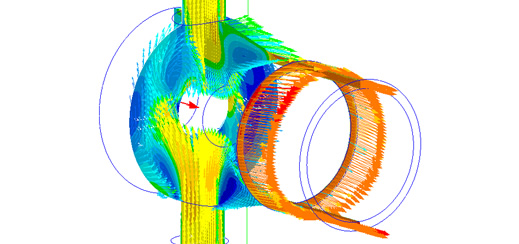

Our team has a wide range of manufacturing experience from both high technology and high volume production industries. During the design phase, detailed discussions will be undertaken with the appropriate manufacturer to ensure optimum design for manufacture and ensure all potential problems are dealt with in advance. When investigating manufacturing options, whether for new product development or machine design and build, we consider many factors such as the technical complexity of the product; materials usage through near net shape processes; environmental, legislative and quality requirements and potential annual volumes. The cost and availability of bought-out OEM product is also considered, along with transportation costs of both raw materials and finished parts.

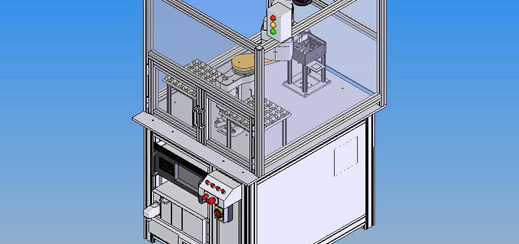

Manufacturing starts with manufacturing route selection, quality planning and supplier selection, ensuring we find the most appropriate supplier. We ensure manufacturing is considered and built into the design of the product or machine at the beginning of the project, to ensure a cost-effective, feasible method of manufacture.

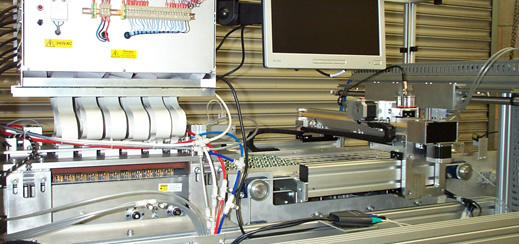

During the manufacturing process, Quadratec will monitor the progress of all the components being manufactured as well as the bought-out items, to ensure that the project programme timescales are being met and to solve any technical problems that may arise.

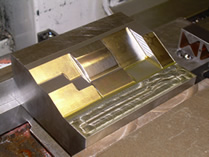

Sometimes products require innovative manufacturing processes, which we carry out with known specialist manufacturers, following detailed consultation with our engineers. This ensures that the manufacturing and inspection systems are properly suited to the product and fully compliant.

The assembly and preliminary testing of all products and machines will be carried out at Quadratec’s assembly facility or, as necessary, at a final subcontract assembly facility. However, this will still be under the control and guidance of Quadratec. Other project specific testing may be carried out at third party facilities, as required.

At the completion of the project, a full set of manufacturing route documentation, build schedules, Certificates of Conformance etc can be provided to our clients.