Composite Design

Advanced glass, aramid and, mainly, carbon composites are now competing in many aspects of engineering product design for high performance aerodynamic, structural and thermal management applications. Furthermore, industrial applications are increasingly becoming the largest user of composites, following aerospace applications and sports equipment. Typical applications are:

- Wind turbines

- Gas turbines

- Energy storage flywheels

- Hydrogen vehicle storage tanks

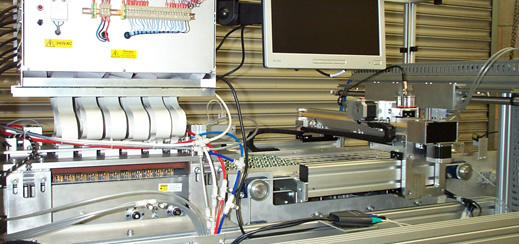

- High-speed and precision machinery

- Robots

- Opto-mechanical systems

- Prosthetics

In addition to composites’ outstanding strengths, stiffnesses and low densities, they also offer unique and tailored physical properties due to their laminate structure and the ability to comform to complex geometries, thus making them an ideal choice for many applications.

Quadratec has therefore ensured we have the capability to design, analyse and manufacture composite structures as one of our key technologies. This is based on the following:

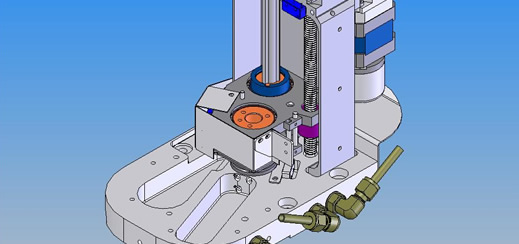

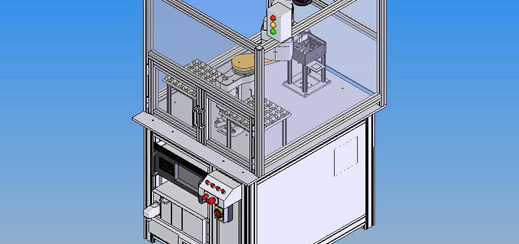

- SolidWorks 3D CAD for product and tooling design

- Laminate assessment software to investigate and optimise different potential laminate structures

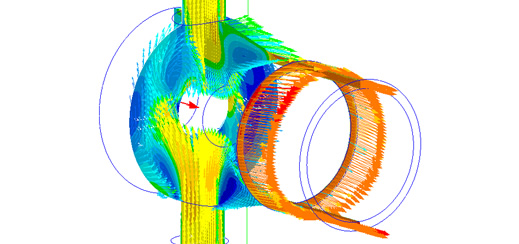

- Finite Element Analysis for overall structural and thermal analysis

- Sub-contract composite manufacturing network for a variety of materials and manufacturing processes

- Digitising of existing parts with complex geometry

Our design team has in depth experience focussing on innovative solutions, weight saving projects and new materials technology. Our composite technology is often used to replace metal structures, with the advantages of no corrosion, no maintenance, no deterioration and +50% weight saving. We specialise in challenging projects completed to demanding specifications and tight deadlines.