Control, Instrumentation and Data Acquisition Systems

As separate projects in their own right and, sometimes as part of the design of larger Machine Systems or Test Equipment, Quadratec design, build and supply Control Systems, Instfrumentation and Data Acquisition Systems.

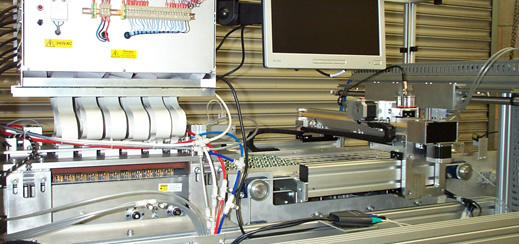

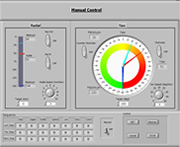

Control is usually via a PLC, with anything from 10s to 100s of I/O signals. The Control System is often mounted in a separate electrical enclosure or 19” rack, with its own Power Supplies, Contactors, Safety Relays, PID Controllers, HMI etc, as required. Sometimes, for relatively small, low accuracy Data Acquisition requirements, the PLC may also be used. On other occasions, Control may be via a PC using National Instruments’ ‘LabView’.

The Instrumentation Systems we provide cover a wide range of measurement types and techniques, depending on the precise measurement parameters required. Most of the Instrumentation Systems we supply are based on existing industrial and laboratory approved instruments and amplifiers, from a wide range of manufacturers. This ensures that we can supply the most appropriate instrument for each application. We also design certain specialist Instrumentation in-house, such as aerodynamic Total Temperature/Pressure Probes & Rakes.

The current industry standard in terms of general Data Acquisition Systems (DAQ) is National Instruments’ (NI) ‘LabView’. This system provides a complete Data Acquisition Software capability, along with many NI Data Acquisition cards. Hence, it is often specified by many of our clients. These systems are usually supplied as a 19” rack mounted Industrial PC, as part of a complete Electrical/Electronic Control & DAQ Unit. This is now the basic standard for many of our Machine and Instrument Data Acquisition Systems. Since many of our clients also have NI ‘LabView’ trained engineering staff, this makes updating and future expansion by our clients relatively easy. To ensure consistent quality Data Acquisition Software, our software programmers are National Instruments’ ‘Certified LabView Associate Developers’.

Typical types of Control and Data Acquisition Systems are as follows:

- Control and DAQ of Speed, Rotary or Linear Position, Proximity, Pressure, Temperature, Humidity, Force, Stress, Displacement or Deflection, Shape & Size, Flow Rates, Level, Vibration, Timing, Number of Cycles, Current, Voltage etc

- PLC Control and small PLC Data Acquisition Systems

- PLC Control & PC Based NI ‘LabView’ Data Acquisition Systems

- PC Based NI ‘LabView’ Control & Data Acquisition Systems

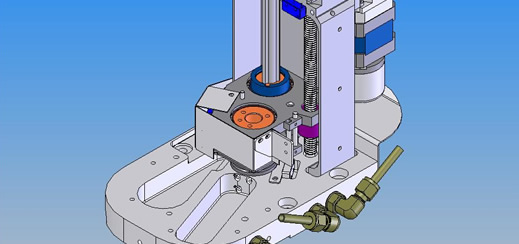

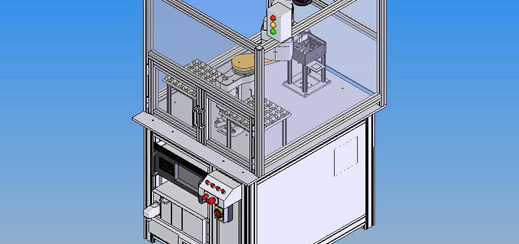

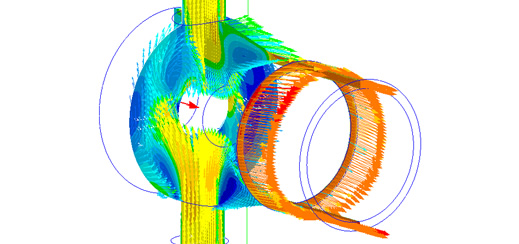

Typical examples of Control, Instrumentation and Data Acquisition Systems previously produced are as follows:

- PC Based NI ‘LabView’ Control & Data Acquisition of a 500 bar Hydraulic Burst Rig

- PLC Control and Data Acquisition of Automotive Brake Pressure Test Machine

- PC Based NI ‘LabView’ Control & Data Acquisition of a Solenoid Electro-pneumatic Response Rig

- PLC Control & PC Based NI ‘LabView’ Data Acquisition of an Automated PCB Testing Machine

- PC Based NI ‘LabView’ Control & Data Acquisition of a 21 Channel Robot Hand Pressure Sensing System

- PC Based NI ‘LabView’ Control & Data Acquisition of a Precision Electro-mechanical Force/Deflection Test Rig

- PC Based NI ‘LabView’ Control & Data Acquisition of Contra-Rotating Turbine Test Rig

- PC Based NI ‘LabView’ Control & Data Acquisition of VAWT Prototype Test Rig

- PC Based NI ‘LabView’ Control of Gas Turbine, 2 Axis Probe Traverse

Some of these are described in more detail in ‘Case Studies’.