Successful Commissioning of two Aerodynamic Automated Probe Traverse Systems for Model Turbine Testing

[30/04/2014]<<back

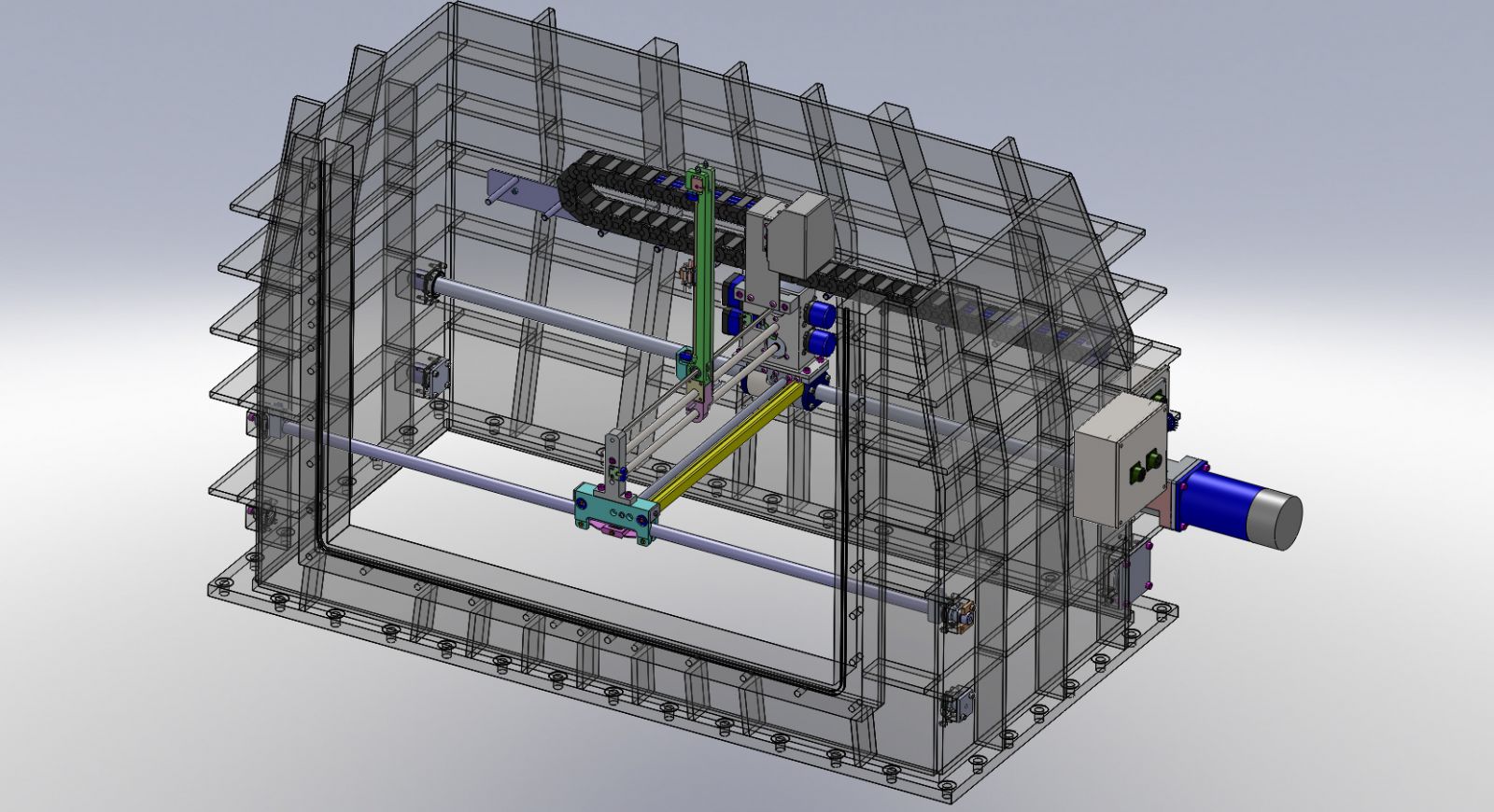

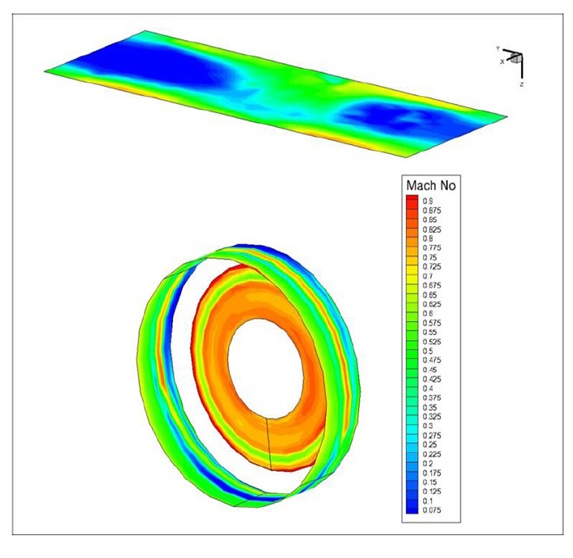

An automated 6 axis Circumferential Probe Traverse System and 3 axis Cartesian Probe Traverse System were designed and manufactured for an Industrial Turbine Model Test Rig, to assess the last stage rotor blade exit and exhaust system aerodynamics. The Circumferential Traverse System traversed two multi-hole, aerodynamic probes across two planes downstream of the turbine rotor last stage, at the diffuser inlet and diffuser exit, and the Cartesian System traversed a single multi-hole aerodynamic probe across an exit plane in the exhaust box system. Successful commissioning and initial running of the two traverse systems has recently taken place.

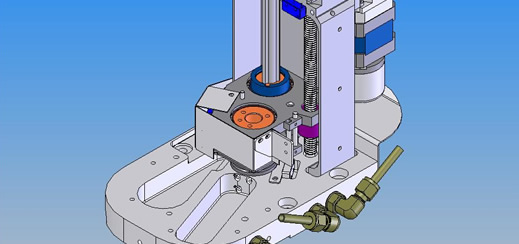

The Circumferential Traverse System was based around a central, rotating hub that supported two different Probe Traverse systems, each in one of two locations. The first Traverse System comprised 3 axes (radial, yaw and pitch) and the second comprised 2 axes (radial and yaw). Based upon an existing Quadratec two axis probe traverse design, these units were adapted to suit the specific application.

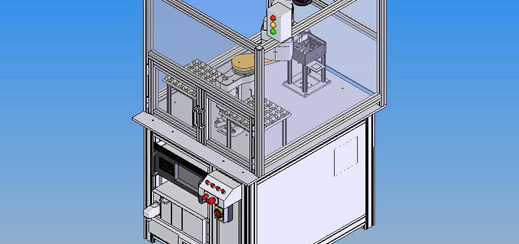

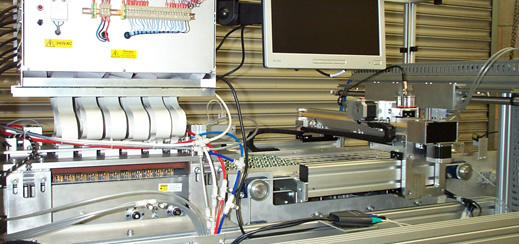

The 3 axis Cartesian Traverse System was designed specifically for the application, being embedded in an exhaust transition duct and designed for minimum absolute blockage, since much of the Traverse System was in the exhaust flow itself. Wherever possible, motors, gearboxes, encoders etc were positioned outside the main flow.

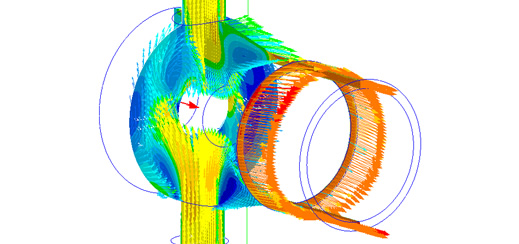

The total system allowed automated traversing of both the Circumferential and Cartesian Probe Traverse Systems simultaneously and completed the equivalent of nearly 600 hours of ‘manual’ traversing. The system achieved an increase in productivity by a factor of 9 over previous manual methods. Further, the Traverse System provided important aerodynamic data that could not be provided by a manual traversing method, so enabling further future improvements in the design of the last stage rotor and turbine exhaust aerodynamics.

The Circumferential Traverse System is shown below, along with the Cartesian Exit Traverse and initial results produced.

Circumferential Traverse System

Exit Traverse System

Exhaust & Circumferential Traverse System Results